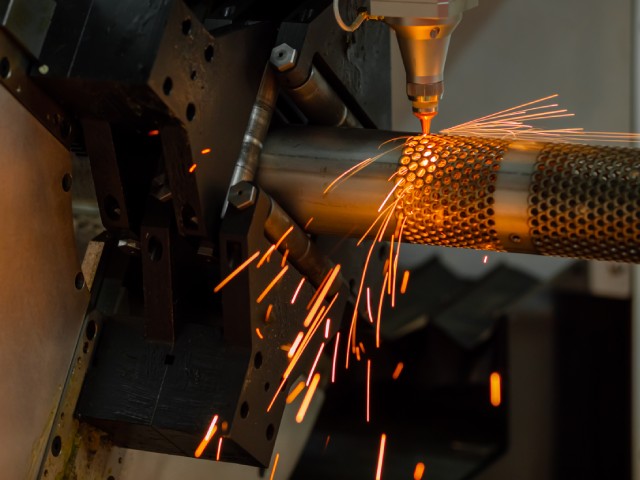

Tube laser cutting is one of the most advanced methods of metal fabrication available today. This advanced technology is reshaping how industry professionals approach their craft.

Despite its many benefits, there are still many misconceptions and unknowns about the method. Below, we’ll explain the key things fabricators should know about tube laser cutting, from the precision it offers to its affordability and efficiency.

Tube laser cutting sets the standard for pinpoint precision that traditional methods often struggle to match. The technique employs advanced computer-guided systems to ensure each cut aligns perfectly with design blueprints, minimizing errors and reducing the need for secondary processing.

Tube laser cutting excels in fabricating complex geometries and intricate patterns while maintaining tight tolerances essential for high-quality assemblies. This makes the method particularly advantageous in precision-critical industries like aerospace, automotive, and medical device manufacturing.

Perhaps the most common myth about tube laser cutting is that while it’s effective and precise, it’s too expensive for many fabricators. Although the initial investment in tube laser machinery may seem high, advancements in technology have made these machines more efficient and cost-effective, lowering entry barriers for fabricators.

Key cost-saving benefits of tube laser cutting include reduced material waste due to optimized usage of tubing and lower operational costs compared to traditional methods. The speed and accuracy of tube laser cutting also minimize labor expenses related to rework, leading to savings that can offset the initial investment.

Another thing fabricators should know about tube laser cutting is it is head and shoulders above other methods in terms of efficient use of materials. Tube laser cutting stands out by consolidating multiple processes into one, speeding up production while minimizing space and resource requirements.

Unlike traditional methods, which often need several machines, tube laser cutting allows fabricators to cut to length, create complex profiles, and engrave parts, all with a single machine. These systems also optimize material utilization through software algorithms that reduce waste and lower costs, while automation enables continuous operation with minimal human intervention.

In the fast-paced fabrication industry, the ability to scale production without compromising quality is crucial. Tube laser cutting technology, combined with automation, allows fabricators to efficiently manage high-volume projects by automating tube feeding, cutting, sorting, and stacking with minimal human input.

This capability is especially beneficial for industries such as automotive, construction, and furniture manufacturing, which require large quantities of parts. By integrating tube laser cutting, fabricators don’t have to choose between precision and volume—they can get the best of both worlds.

Tube laser cutting represents a paradigm shift in the fabrication industry, offering unparalleled precision, growing affordability, unmatched efficiency, and high-volume potential. By leveraging these advantages, fabrication professionals, metal workers, and industrial engineers can enhance their craft and maintain competitiveness in a changing market.

24World Media does not take any responsibility of the information you see on this page. The content this page contains is from independent third-party content provider. If you have any concerns regarding the content, please free to write us here: contact@24worldmedia.com